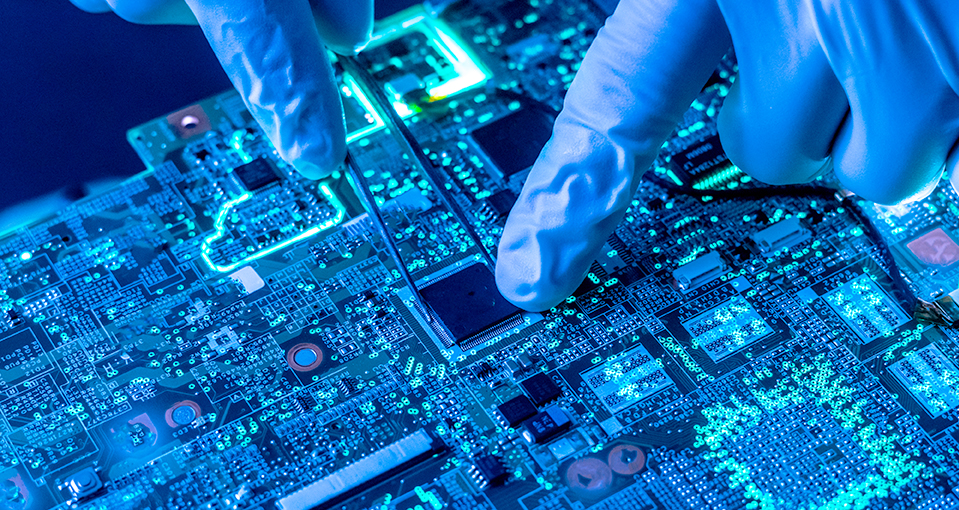

Heat Dissipation Adhesive for semiconductor

The biggest topic in the automotive and electrical and electronic fields is

“how to fuse many electronic devices to be lighter and thinner”. As customers

demand smaller, thinner, lighter and more versatile, the elements that make up electronic

devices are being used more and more closely.

Due to the high integration of these electronic devices, electronic products generate more heat,

and the heat emitted from the inside of the product deteriorates the functions of

peripheral devices and causes malfunctions and substrate deterioration.

Accordingly, the demand for “high heat dissipation materials” that can effectively dissipate

heat is increasing, and semiconductor heat dissipation adhesives are used in such places.

Fine Nano’s Heat Dissipation Adhesive

- Copper-based heat dissipation adhesive

- Silver-based heat dissipation adhesive

The role of Fine Nano’s

Heat Dissipation Adhesive

This is advantageous for manufacturing parts that consume

high power and generate a lot of heat, such as power devices and

LED modules, because the thermal conductivity of the base metal

substrate can be used.

The application market and use of

Fine Nano’s Heat Dissipation Adhesive

It is applied to high heat dissipation areas in automobiles and

electrical and electronic fields, and serves as a core material that

helps prevent deterioration of semiconductor performance through

optimal heat dissipation.